|

September 29, 2023

Interview: Libre Solar

By the Open make team and Michel Langhammer. Copyright to the authors,

distributed under a CC-BY 4.0 licence.

Sections:

Banner image: libre solar logo, distributed under a CC-BY-SA 4.0

Date: 2022-08-02

Interviewee: Michel Langhammer

Interviewers: Robert Mies (TU Berlin) & Moritz Maxeiner (FU Berlin)

Transcription and editing: Diana Paola Americano Guerrero, Robert Mies, Fabio

Reeh, Moritz Maxeiner & Julien Colomb

Screenshot of the interview.

The Libre Solar in a nutshell

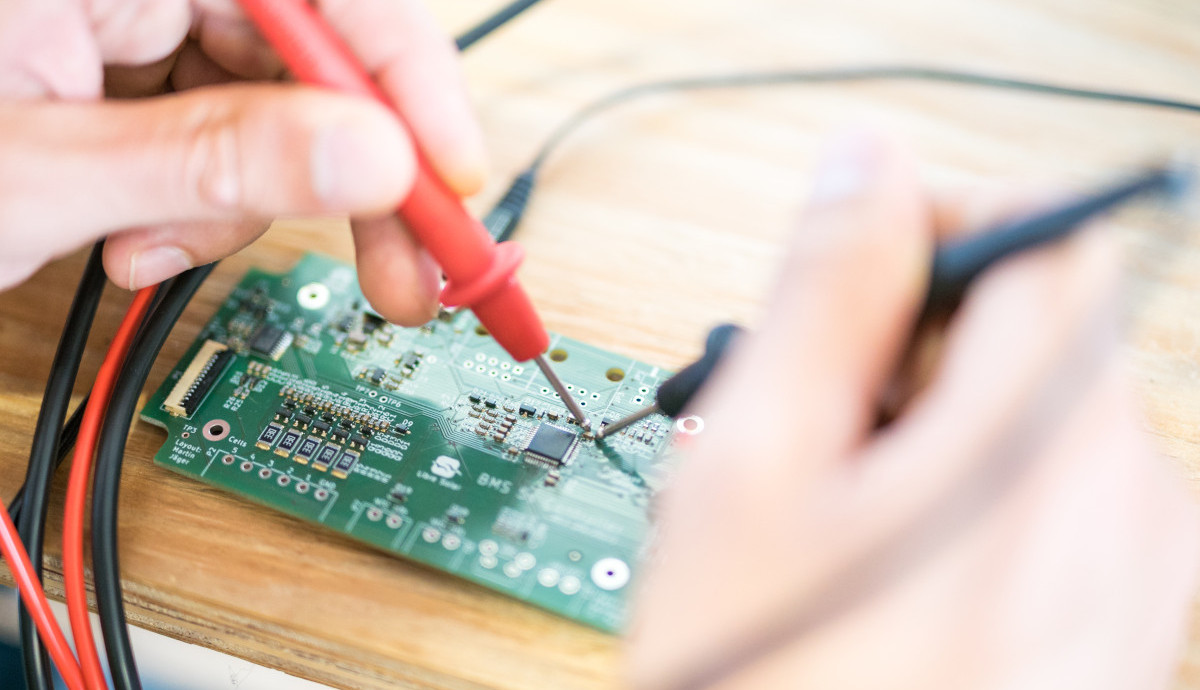

Image of the BMS circuit, by libresolar, distributed under a CC-BY-SA license.

- Main website: https://libre.solar

- Project start: 2015/2017

- Core development team size: 7 people

Hardware products

The project propose building blocks for direct current Energy Systems: Charge Controllers, Battery Management, Interfaces and other elements.

The libre solar is a set of (mostly electronic) products like a portfolio.

You have different components for different requirements and can mix them to build up a system.

Hardware maturity

Different products are at different development stage, it is declared for each

product on the website: alpha, beta, eval, and release.

Rebuilds

We have test fields of friends who are living in rural areas. They build up the off grid energy system completely by themselves.

The project

It was developed in Hamburg by Martin Jäger, who’s the main developer and founder of the Libre Solar project.

Martin Jäger is a mechanical engineer. For him, it was tinkering around and learning about power electronics and software development. In 2017, people started to kick in, mainly in the firmware development.

When I jumped in concerning the educational resource, the benefit was to have open source resources for redesigning new components.

How did the project Libre Solar started?

Show answer

The Libre Solar project started in 2017. It was an

already existing set of electronics developed by Martin Jäger, who began in

2015. It all started with a Arduino based charge controller for photovoltaic

systems. It was back on Arduino base with low entry and later developed to a

next generation of electronic charge controller with a STM 32. The higher demand

regarding resolution and calculation time required the upgrade of the hardware

component.

Further we built the Libre Solar around or with that component and

started prototyping. There were different prototyping phases of different

components. It was always developing one component and testing it. Based on the

test we implemented new requirements. An example would be power classes and how

to get a higher current out of the system. There were different development

stages from the component. Now it’s a set of hardware components used as charge

controllers. Besides, it’s a different set. It’s for battery management systems

and a modular setup, in case you want to use different types of batteries. You

need a different type of components, for example, a battery management system

for lithium ion batteries, if you want to use them.

There were different prototyping phases of different components. It was always

developing one component and testing it. Based on the test we implemented new

requirements.

We do not write down the issues, we just make an iteration of the documentation.

We did the entry workshop about how to use Git with a colleague of ours. GitHub

is really comfortable because you have version controlling and all this DevOps

functionalities behind it.

Where was this developed?

Show answer

It was developed in Hamburg by Martin Jäger, who’s

the main developer and founder of the Libre Solar project. He mainly developed

this by his own in the beginning. Later, people started to kick in, mainly in

the firmware development. First the hardware was development of the PCB

electronic layout and afterwards the firmware. In the firmware development was

another contributor who kicked in mainly concerning the modularization of the

software. We have one main firmware repository where we can modularly choose the

different type of hardware and the firmware adapts to that.

What was the core benefit of this project? How does the hardware fit in the

overall project?

Show answer

The main benefit from the Libre Solar project was

learning about about power electronics. Martin Jäger doesn’t come from the field

of electronic development, he’s a mechanical engineer. For him, it was tinkering

around and learning about power electronics and software development. It’s

mainly the benefit for him as a developer. When I jumped in concerning the

educational resource, the benefit was to have open source resources for

redesigning new components, like our Libre Solar Box where we can develop an

application out of the electrical component from the Libre Solar project. This

was the benefit from my point of view as a student. The benefit for the people

who are using the component is to build it by themselves. We have test fields of

friends who are living in rural areas. They build up the off grid energy system

completely by themselves. For example, there were users in South Germany who

rebuilt the charging sensor node in a rural area. Besides, we have research

projects. As example, in Rwanda in Africa, we built up a test system with these

components. The benefit there for the people is that they can run an energy grid

system with open source hardware components. They are now able to redesign it by

themselves. But the knowledge level is still needed to know how to adapt and how

to redesign it. There’re different layers of benefits.

The first development stage was made without funding.

Open educational resources creation was funded by the city of Hamburg by the Hamburg Open Online University.

(All the money wasn’t spend on people but on external resources.)

A research fund from Scotland helped with development together with partner startups.

The university didn’t have the infrastructure for us. That’s why we went to a Fab Lab.

How were the different parts funded?

Show answer

The first development stage was voluntary funded.

All the development was made free. At the education project we derived open

educational resources out of the existing design documents. This was funded by

the city of Hamburg by the Hamburg Open Online University. This was one funding

pot mainly for creating educational resources. And then the research projects.

Another funding was a research project from Scotland together with partner

startups who are interested in this field. This was financed by a research fund

from Scotland.

Did the Rwanda project come from Scotland as well?

Show answer

I think this was from Scotland.

How much money did you receive overall? Can you provide some ballpark numbers?

Show answer

I don’t know the size of the overall funding on the project. I have numbers for

the educational part. It was around 70,000. It were two funding rounds where we

got money. For the Rwanda project I have no numbers.

Could you describe the overall process? How did you organize it?

Show answer

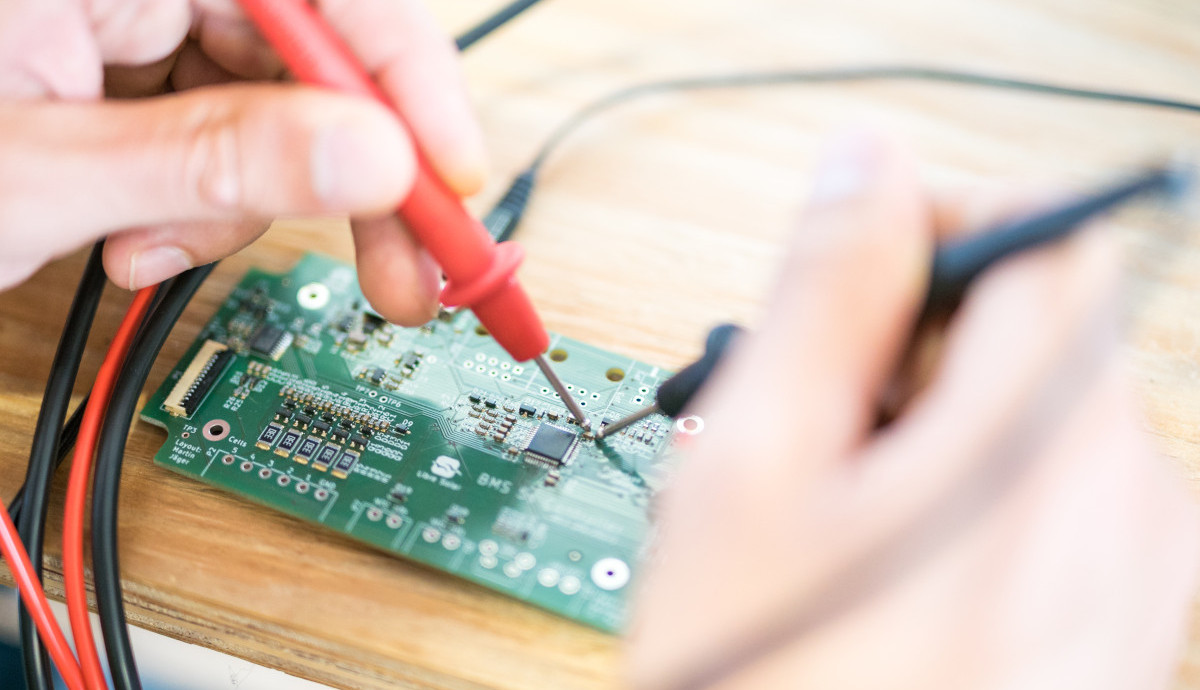

With our student group, we replicated the Libre

Solar component, it was a community based workshop run in a FabLab. In the

planning process, we got a bill of materials and saw what components we needed.

We divided the replication into PCB replication and the actual solar box

replication. Within PCB replication, we decided between to order a full assembled

PCB or to order the circuit board without parts on it. It was like the PCB

without components. With the ordered components we went to the Fab Lab and did

the usual process steps to do for electronics. Afterwards it was about testing

to see if all the components were assembled in the right direction and currency.

Then we flashed the PCBU. Finally, we had a ready to use charge controller.

How did you organize the development process?

Show answer

So the development process for the PCB mainly took place in GitHub, as as a collaboration platform. The repository is placed in GitHub. For the electric design, I’m using KiCAD as an offline development tool, to design the component. And then, you placed ready design files in place in Github, and make some comments. We used the Git workflow, you have there and yeah. So this about development, using the tools on GitHub and then iterating.

It’s like the usual software kit workflow where you have other people who contribute, make a pull, push or merge requests or give comments.

Different people are working with different styles and the documentation gets a little bit unstructured and messy,

contribution guideline for the hardware design help mitigate these issues.

If you don’t have proper documentation, people don’t have a good starting point where they can jump in the development.

Within the forum, you can see a lot of people who are interacting and making questions because they replicate the components by themselves.

We had a telegram channel where we had ad hoc communication. We built up a GitHub repository where we had issue-based coordination. We had weekly meetings at a Fab Lab.

About contributors: A review was there because it was from friends. We

had the direct contact. It wasn’t on a GitHub sphere or distributed community

sphere.

Would you do this from different locations?

Show answer

The electrical design is mainly developed by Martin.

I have to look up if there’re some other comments. Especially in electric

designing, hardware is designed without many contributors because you need

technical knowledge. It’s like the usual software kit workflow where you have

other people contribute, make a pull, push or merge requests or give comments.

That’s a typical good workflow.

From the development and production side the main issues was safety, quality and secureness. Especially when you work with batteries some people have been insecure how to handle the safety issues: You can’t shortcut them otherwise they will explode.

[Getting feedback was difficult]: A review was there because it was from friends. We

had the direct contact. It wasn’t on a GitHub sphere or distributed community

sphere.

During that process or the project overall, what major issues have you come

across and how did you resolve them?

Show answer

About development process issues, I can’t tell much

because Martin is the main developer. I know there are issues regarding

contribution guidelines. Especially for the firmware, you stick to a code style

but different people are working with different styles and the code gets a

little bit unstructured and messy. For people to learn the code, it’s important

to have a common structure. This was one case of a contribution guideline for

the hardware design, but I can’t say too much because I’m not too much

contributing in it. If you don’t have proper documentation, people don’t have a

good starting point where they can jump in the development. A proper

documentation is crucial.

The same counts for modular development that people

can contribute to specific modules or sub-components of your hardware. From the

development and production side, the main issues was safety, quality and

secureness. When you work with batteries some people have been insecure on how to

handle the safety issues. You can’t shortcut them otherwise they will explode.

There you need expertise and a guide how to trust the people you’re working

with. Some of us had an electrical background. The people, who didn’t have the

background in electrical engineering were more insecure about handling

batteries.

Did you them some idea what not to do?

Show answer

This was one issue besides the quality testing. For

quality parameters, there was not so much documentation done. About this, we depended on

expertise.

Did you receive some outside expertise from people?

Show answer

We had Martin as the main developer with the main

expertise. If he wasn’t there, it would have been harder to do the quality test.

Martin made most of the decisions because he had the main expertise.

For the educational part, it was made in a group of seven people by consensus.

How were the decisions made within the project all the time?

Show answer

Martin made most of the decisions because he had the

main expertise. What he said should fit. Other people had expertise which been

discussed. For the educational part, I was the project leader on the

administration side but I didn’t make any decisions. It was made in a group of

seven people by consensus.

The hardware

What hardware components have you developed in this project?

Show answer

It’s been mainly electronics (PCBs).

Were those PCBs parts of multiple products or were they all part of the same

product?

Show answer

I would call it more a set of products like a

portfolio. You had different components for different requirements. You could

mix them to build up a system out of it.

Could you give maybe a quick overview over those products or are there too

many?

Show answer

No, it’s similar to charge controllers. One product

is like DC-DC converters and charge controllers with different types depending

on power class. The second type is a battery management system which have

different types depending on how many cells you want to connect. The third are

communication gateways to connect to server-based applications.

How would you classify the products in terms of mechanical, electrical

andsoftware?

Show answer

First was the electrical classification.

Did you have some mechanical issues, e.g.with the panels?

Show answer

No, the panels, batteries, cable and plugs were

sourced. Everything was sourced. There was no mechanical frame. We had a solar

box. This is one application but it’s not the main component of the Libre Solar

project, it’s in our student project. The solar box has a mechanical frame we

can consider. The Box is one application you can make. Firmware would be another

class.

How would you rate the maturity from prototype, demonstrator to market ready?

Show answer

We declared on our website the different development

stages. I don’t have it all in my head. If you look here, you can see the

development stage declared for each product.

Have these hardware components been built, produced or modified by others

outside of the project independently?

Show answer

Yes, definitely. We had a maker space in South

Germany who replicated one charge controller completely by themselves, we didn’t

even know about. Afterwards they sent us a link to the forum when he discussed

it. They replicated it and used it for a sensor node as well. This is one

independent replication of the component.

We have a forum in the project. Within the forum, you can see a lot of people

who are interacting and asking questions, because they replicate the components

by themselves. I don’t have an exact number.

Is the project still ongoing and you’re working together in a group?

Show answer

The hardware development of the electrical layout is

mainly done by Martin Jäger. I have to look in the GitHub[*] if there are more

contributors. I’m doing the educational part. I’m designing the resource

contents for education. Katherine, who was in the Open Hardware Summit, works in

the educational part because she’s in the library and does a little bit of

software for data visualization. On the data software side are contributors, but

we aren’t in a local group here in Hamburg. It’s distributed in the world.

[* Notes from the open make team: not many more contributors spotted on GitHub, although the projects are often forked.]

Are you all working on the same hardware what can be found on the repository?

Show answer

Yes, everything around the hardware components

within the Libre Solar project.

Research outputs

What were or still are the envisioned outputs of the hardware development in

terms of publications, the hardware itself, documentation, learning and

experience?

Show answer

My wish is to build up Libre Solar as the Arduino

for renewable energy systems. I always wanted to have an open hardware base for

learning and building up its own renewable energy system for everyone. It’s for

industrial, private or educational use. We aim for a ready to sell product and

we are nearly there. It’s just because of the CE certification. We already did a

few tests in the laboratory for measuring the CE standards but we were out of

range and didn’t get the CE certification. That’s why we can’t legally sell the

products, but it’s a goal.

Right now we have the supply shortage of

micro-controllers which causes the prototyping process to hold, because we can’t

source STM 32 micro-controllers. In the beginning, the goal is to have a set of

hardware components ready to sell with a portfolio for educational reasons and

research institutes. There was a connection with the University of Freiburg and different

other universities are interested. This is a low entry point because you

don’t need the proper certification if you just use it in research environment.

Would those be your customers?

Show answer

This would be one channel. For example, we think of

sensor nodes for agricultural applications, which we test here in Hamburg for

loading stations for mobile farm. It’s energy supply, we can use it for nearly

everything which needs electrical current.

Do you combine the Libre Solar with other hardware?

Show answer

The hardware is just a load for us.

What do you think about publications in scientific journals or in hardware

journals?

Show answer

It’s not the main goal. I’m a researcher now. I

talked with Martin about the publication of one paper, for example, from Joshua

Pierce on Hardware X. There you can publish open source hardware projects, but

it’s not the main focus.

Did you publish project findings in relation to the hardware like issues you

faced in the development process and what you learned in the development

process along with the individual bill of materials, CAD files, assembly

instructions, guidelines, essentially and everything you found out during the

process of development?

Show answer

Not specifically, our feedback or the issues is that

we make an iteration of the documents and republish the documentation. If we see

that there is something missing within the documentation, we redevelop the

documentation and publish it. But it’s not explicitly a publication about the

issues. We’re thinking about a blog. If you have a blog post, you can say: ‘here

is something we made’. It’s a little bit like issue tracking using GitHub. While

we were in a replication workshop, we didn’t write down the issues. We just make

an iteration of the documentation.

The research output was the hardware itself and not any publications around

it?

Show answer

Yes, no publications.

What kind of information have you shared in terms of the bill of materials,

CAD files, assembly instructions, warning and safety guidelines.

Show answer

I could have a look in the repository. It’s mainly

for the hardware with common information like design files, CAD files and

interactive bill of materials. We didn’t provide an assembly guideline for

electronics but we made a guideline how to source the components. It’s like our

educational resource website where we put in everything concerning assembly

processes.

We published it only on GitHub. There’re some linking to the wiki from Open Source Ecology in Germany.

Open Source Ecology helped to disseminate or promote the project in a way.

We provide information on different platforms to draw more people for us and the Open Source Ecology.

How did you publish the hardware?

Show answer

We published it only on GitHub. There is

linking to the wiki from Open Source Ecology in Germany. The key entry in this

platform is describing a so called Open Nano Grid. This would be another

application you can make with hardware components from the Libre Solar project.

Why did you choose GitHub and the Open Source Ecology?

Show answer

GitHub was like the poster in this time, Martin

Jäger choose it. I think it was the most common collaboration platform for

software development and electronics. It’s really comfortable because you have a

version controlling and all this DevOps functionalities behind it.

Was using this platform for development easy or have you faced any barriers?

Show answer

The starting point is a little bit tricky. For

people, who come from outside and aren’t aware of software, it’s hard to

interact with GitHub or Git-based repositories.

Why didn’t you publish issues you came across? Was there any active decision

making?

Show answer

No, I think it wasn’t a high quality notes document

that we had. We didn’t have the time to make it in a qualitative documentation

to publish.

The creating of more content is limited by the amount of people, time and financial resources. Everything is on a voluntary basis.

With master students from electrical engineering, renewable energy systems and mechanical engineering, we mainly replicated the Libre Solar hardware and redesigned the solar box.

I was introducing it to all the courses. They wrote me they were interested.

We used a typical forum where people can add questions and threads.

It’s very good because you see people contributing in this topic.

This shows that different people come with different requirements.

Is there something else besides the time constraints?

Show answer

Yeah, that’s one of the main main components and

maybe the amount of contributors. If you have more contributors who feel more

safe with the thing you develop, you will get more feedback and you can optimize

the product better. When Martin Jäger is the only developer here, he always

doesn’t know if the design is the best design. The feedback on hardware design

is crucial besides a lot of contributors.

It would be easier because now you’re developing and you maybe know that the

quality is quite good but you don’t have the direct feedback. Because we don’t

sell the product, we don’t have a customer environment feedback process. For

now, there’s not so much qualitative feedback for the design.

Since the project has been reproduced in independently, did they need to

reinvent anything or did they have all the information they needed to

reproduce it?

Show answer

From the independently replicated parts we don’t

have any qualitative feedback. I can just assume and you can analyze the forum.

How did you handle problems with GitHub?

Show answer

It’s easy for people who have a technical or

software development background. We did the entry workshop about how to use Git.

(Yeah, okay.) A colleague of ours did a little workshop. The graphical interface

of GitHub makes it much more easy using it and it was like trial and error or

working with it together. It helped to focus on the main features. With time the

people got used to it. It’s like a learning curve for platforms.

Could you explain the connection to Open Source Ecology Germany?

Show answer

Yeah, it wasn’t directly to GitLab from Open Source

Ecology but to the wiki from Open Source Ecology. (Open Source Ecology

Germany is running a wiki). There they can maybe just search for the entry. It

was like one article where they mentioned the Libre Solar project. But we are

documenting it mainly on GitHub. Other people, who are reusing the component,

are documenting it and the key focus was ecology. They helped to disseminate or

promote the project in a way. Some people informed others that there’s this

component you can use to build up an open nano grid. This was the system they

introduce. Therefore, they link to the Libre Solar project and say that this is

the open hardware component you can use for building up such a system.

All right. And so you you use these pages as well, I mean, I see I see your

name here. You use this to and to draw more people, I guess, at least a couple

of people.

Show answer

We provide information on different platforms to

draw more people for us and the Open Source Ecology. That project pays to show

the interlinking or the collaboration between the organizations. Indirectly,

it’s to draw more people and to reach out from the different organizations.

Could you explain the connection with the POC 21 of Libre Solar?

Show answer

I wasn’t involved there, this was before my time.

Martin Jäger attended at the POC 2021 meeting in Paris. I don’t know how he got

there and under which circumstances. He was asked for something that I don’t

know. He got to know different people from this from the Open Source Hardware

community and they’re still connected there.

I think because the documentation is there. They’re replicating it.

The second part in the educational part is the production.

We have development and production stage and now the usage stage. Each component has a user manual.

It would contain the data acquisition, data analyzes of energy systems and improvements.

The fourth stage would be recycling or upcycling of such components.

How would you classify the overall information you’ve put out?

Show answer

The main clustering was the hardware, education and

maybe the website. Then it’s three or four if you want to consider the forum as

an information base. It’s like the hardware information. This was mainly the

repository you have on GitHub. The hardware information is consisting of the

design files, BOM file, readme file and an overview. This is the technical

documentation of the hardware. It’s one main information cluster. For all the

components, a separate or a dedicated repository exists with these informations.

The second information cluster is the learning cluster. It’s the

open education resources. The main idea behind it is to give a basic information

about the used technologies within a system. It’s divided in two chapters. One

is a system view to have an overall view of what we are here talking about

regarding the nano grid system, renewable energy and PV battery. The second part

is the component part. It’s to dive in into the components. For example, how is

a charge controller built up? What does a charge controller contain? It has a

power electronics, measuring and communication stage. I’m clustering it in the

sub-components of the hardware. The idea behind it was that people who want to

contribute in the development have a starting point of what do they want to

develop. If you have an electrical engineering background, you don’t need this

because this what you learn in university. But if you don’t have and you’re

interested in renewable energies, you can use the educational resources to get

the basic overview.

The second part in the educational part is the production.

It’s about how to replicate and produce such components. I’m oriented on the

life cycle process. We have development and production stage and now the usage

stage. Each component has a user manual. For learning environment, user usage

and documentation it would contain the data acquisition, data analyzes of energy

systems and improvements. But this isn’t yet developed. The fourth stage would

be recycling or upcycling of such components.

All right, yeah.

Show answer

The forum was a typical forum where people can add

questions and threads. It’s very good because you see people contributing in

this topic. There is one about the development of a new charge controller and

this was a very active thread where people give their feedback to it. It went on

for some time. It results in a new development of a hardware. This shows that

different people come with different requirements and make up their mind for the

development of a new 20 ampere maximum power point checker.

Is this on your own website again? It’s like a repository blog.

Show answer

It’s made with static site generator called

viewpress and a git repository. There’s a framework and broad usage. Within

viewpress are different content blocks. This forum is based on this course an

open source forum platform.

Do you publish everything there?

Show answer

GitHub is the main backbone of all information and

data. It’s linked to two other front end websites.

Did you publish everything you have?

Show answer

Yeah, everything is published. For example, the main

development of the battery management system, which got funded by energy access,

is within one repository. Energy access funds open hardware project in the field

of renewable energy.

The creating of more content is limited by the amount of people, time and

financial resources. Everything is on a voluntary basis.

Successful is the ready to use prototype we developed.

In my opinion, it’s a very high quality documentation of all the components,

it’s very structured. We were able to develop educational resources within such

a hardware project which isn’t typical.

The idea behind the open education resources was that people who want to

contribute in the development have a starting point of what do they want to

develop.

The feedback on hardware design is crucial. It would be easier with a lot of

contributors. For now, there’s not so much qualitative feedback for the design.

It would be nice to have more contributors dedicated on the electrical hardware

design.

If we would have people who manage the feedback and community work, we could get

more qualitative feedback out of it.

What was successful and what wasn’t about the project?

Show answer

Successful is the ready to use prototype we

developed. I would declare it a prototype because of this legal issue of the CE

certification and not call it a product. It’s ready to use and people are using

it with off grid applications all around the world. We have a feedback loop from

the research project how the system is running: It’s running. This is the main

success. The documentation is a success, too. In my opinion, it’s a very high

quality documentation of all the components, it’s very structured. We were able

to develop educational resources within such a hardware project which isn’t

typical. The contribution in the hardware design is improvable. This is still a

gap. It would be nice to have more contributors dedicated on the electrical

hardware design. We had some reviewers which was good. We need to know how to

improve the EMC within the electrical component. There was a review but not an

active contribution to this.

What kind of contributions are you looking for?

Show answer

A review was there because it was from friends. We

had the direct contact. It wasn’t on a GitHub sphere or distributed community

sphere. It would be nice to have a review and improvement suggestions for the

design. A complete redesign isn’t the goal behind it. If someone would redesign

it and make a suggestion, that would be very cool. But it’s not the main goal.

Do the universities and others, who are using it already, contribute ?

Show answer

They don’t contribute in the electrical electrical

layout. I think, the users are mainly people who need the current and want to

have renewable energy. The main reason is always the software part. You have

open interfaces where you can extract data out of it and you can control data

out of it. You have the operating power for the system. You can use it for your

requirements. If the current flow is not 99%, these users doesn’t care about if

they see a failure. Till now, they wouldn’t contribute to erase this failure to

improve function.

How do people use it? Do you sell it and they put it together? How far is the

reach of the hardware?

Show answer

They’re building it by themselves. I think because

the documentation is there. They’re replicating it. We had one hardware where we

made a little batch of 100 components and this was sold. Now the batch is empty.

We had no CE certification for one component, therefore it was only for

educational and tinkering purpose. Another example, at the CCC Congress we had

around 10 and we sold three out of it. It were Universities from France and UK.

The third I don’t know anymore, but there were people who were interested and

said to buy a new one, because they have a research topic and it costs like 50

or 60€. There were distributed server applications and they wanted to test how

servers can run on renewable energy systems. This was the perfect use case for

them because they can extract all data out of the charge controller and they can

correlate with their process data. They are still running on those parts and

sharing with us information.

If we would have people who manage this feedback and community work, we could

get more qualitative feedback out of it.

Participants

What brought you to this project?

Show answer

At this time, I was a member of the Open Source

Ecology association in the field of open source hardware community. I was

attending some lab meetings. I was definitely convinced by the idea of open

source hardware and I was intrinsically motive interested in renewable energy

systems. I studied electrical engineering with the focus on automation systems

and therefore my interest are energy systems and the automation aspects behind

it. When I moved to Hamburg, there was one member of Open Source Ecology who

said to me that there is the Libre Solar project and Martin Jäger, the

developer, lives in Hamburg. This was a coincidence. Besides I found a call from

the open Hamburg online university to contribute to a project of open education

resources. Afterwards I made a concept to build a box which I’ve seen in the

Open Source Ecology wiki. It was a solar box. But it used different types of

PCBs of solar charges. At this time, it was a solar charger developed by a

Canadian developer. So my idea was to take this solar box and take the Libre

Solar components out of it. I already had the electrical expertise to design

this a little bit in my head.This was when I called Martin Jäger and introduced

him to this idea and he was interested. That’s how I jumped in. It was mainly

within the development of open educational resources.

Was this like a thesis or how did this project start?

Show answer

It was a funding project of the Hamburg Open Online

University. They had a funding round and they were very interested of students

who contribute. At this time it was mainly professors, researcher and staff. I

was like a student which they were very interested in. This time I got funded.

It was like 25,000 Euro. It was like the first funding project for me. I was a

completely inexperienced with such things. I was just a student.

My professor was the mentor because that was needed from the Hamburg open online

university. I was a student and the project leader of this funding project.

That’s how we started. In this project we didn’t pay any people. This was my

idea to have people who are intrinsically motivated who would join without

money. We took all the money for buying hardware, to rent fab labs and the

machines and producing a promo video. It’s a little YouTube video of introducing

open source hardware. All the money wasn’t spend on people but on external

resources.

Have other grants been used to pay people?

Show answer

The second grant we get was used to pay student

assistants. They created the content. Our idea was bigger and it was to much to

write this content all in our free time.

What were the occupations of the people who contribute?

Show answer

It wasn’t directly to the Libre Solar project. With

the beginning of this open educational resource, I started a student group with

my professor as a mentor and we called the student group “collective open source

hardware”. „Cosine eight" was the name behind it. We were the seven people in

the student group. We mainly replicated the Libre Solar hardware and redesigned

the solar box.

Were all of you students? Could elaborate if there’re other postdocs or

professors.

Show answer

My old supervisor, or professor, wasn’t in the

content. He wasn’t really part of it. He was very interested and he gave me all

the possibilities. I started to introduce this project in all courses within the

university. I jumped in 20-25 courses and introduced it to the students with his

help because he introduced myself. It made it a little bit easier to introduce

my project because he said it’s a good project and you should listen to it. In

the group we were students and Martin Jäger has a PhD degree. He worked part

time in the automotive industry and part time developed the Libre Solar project.

The others were all mainly master students from electrical engineering,

renewable energy systems and mechanical engineering. In the Hamburg open online

university we had some communication designers who did the logo and other icons.

They designed it for us or helped us to design it. They were employed at the

Hamburg Open Online University. It was a service they gave us for free.

How did you find all these people?

Show answer

I was introducing it to all the courses. It acquired

them by myself and some of them I knew already. With two of them I had direct

contact and the others were interested after introducing it. They wrote me an

email and told to be interested.

We had two students who made their student project work in this area. They took

a solar box and made the testing. They tested all the parameters of the solar

box, for example current versus saturation. But it didn’t went so good to be

honest because they didn’t document anything. It was for them to do it but not

on a qualitative level. They just did it for getting the credit points without

the open source community documenting. It was a project work they had in one

course.

Did all students receive credit points for the work?

Show answer

No, it were only two of them. They said they had to

do a project work. They asked if they can do this project work in this field.

For myself, I didn’t get any credit points because we didn’t have a project work

where we could use this for. But I did my master thesis in the Libre Solar

project. I asked my professor if I can do my master thesis there. I introduced

the topic, it was about control systems

Some students perceived a benefit, they could get credit points. For the others, it was fun. You’re playing football and others are tinkering in a Fab Lab.

It provided a learning effect. Application oriented learning I would call it now.

How did the different members benefited from the work?

Show answer

I think, Martin Jäger’s was happy that people were

interested in his project. In terms of community reach out, this supported

community building for him. The main idea of the student group was to get more

students in the field of open source hardware. In 2017, no students knew what

open source hardware is. This was in my field, I was very pity that no one knew

what open source hardware is, especially engineering students, because there’s

so much potential behind. It’s still the case. I think, this was for Martin a

motivation because we talked about it. He said that’s a good idea to disseminate

the idea of open source hardware within engineering students. Some students

perceived a benefit, they could get credit points because they had this project

work where they got credit points. For the others, it was fun. You’re playing

football and others are tinkering in a Fab Lab. For some, it was the first time

of manufacturing. For example, I studied electrical engineering and I’ve never

picked and placed a PCB. I’ve never saw a PCB production. It was in theory

taught but we never experienced it in the laboratory. It provided a learning

effect. Application oriented learning I would call it now.

Who got paid from the grants?

Show answer

Martin Jäger got a little bit of this money because

he has this high education level and he put a lot of time in it. We said to

Martin to write a receipt because he’s working so much in this field. Even

though he didn’t want it to but we said that’s money for your work. Besides we

did the video I mentioned. It was a video creator who got paid for doing

information videos.

Didn’t anyone receive payment for a longer period?

Show answer

In the second phase we got students paid as student

assistants and paid students for creating the content.

How many student assistants did you have?

Show answer

We had two. I think they worked for a year or a year

and a half. There was Corona and maybe it was extended by half a year.

Was all of this still at the Hamburg Open Online University situated?

Show answer

All of this was at the Hamburg Open Online

University.

How did you coordinate the work?

Show answer

The coordination of the development was quite easy

because Martin was the only developer at this time. The software development

coordination went through Git. The research projects had a typical research

project coordination with Martin as a partner. But I don’t know the exact

constellation of the research project he worked with. For our student work the

coordination was made by me. We had a telegram channel where we had ad hoc

communication. We built up a GitHub repository where we had issue-based

coordination. This was a little bit of our project management behind it.

Besides, we had weekly meetings at a Fab Lab. This was every Thursday, it was

meeting in the evening with discussing and thinking about the design and

requirements. It was in the Fab Lab St. Pauli.

Martin was there before us. His first prototype and first testing system was

build in the Fab Lab St Pauli. At the Fab Lab St. Paul was a solar panel

charging a battery. This is why we went to the Fab Lab St Pauli, too.

Why didn’t you meet at the University?

Show answer

The university didn’t gave us a room. We asked for

it. They brought us then in an old laboratory, where we could hang around. But

this isn’t a good place to work. Then they build up a Fab Lab but it wasn’t open

for students. We asked for it but it’s just for start-ups and some ecosystem

share stakeholders.Further, there was a Fab Lab with 3D printers. But it wasn’t

a Fab Lab where you can like tinker around, it was just for 3D printing. The

university didn’t have the infrastructure for us. That’s why we went to a Fab

Lab.

How many members were in the project?

Show answer

We were seven people.